Empowered Engineering

How ShipConstructor can help your Business

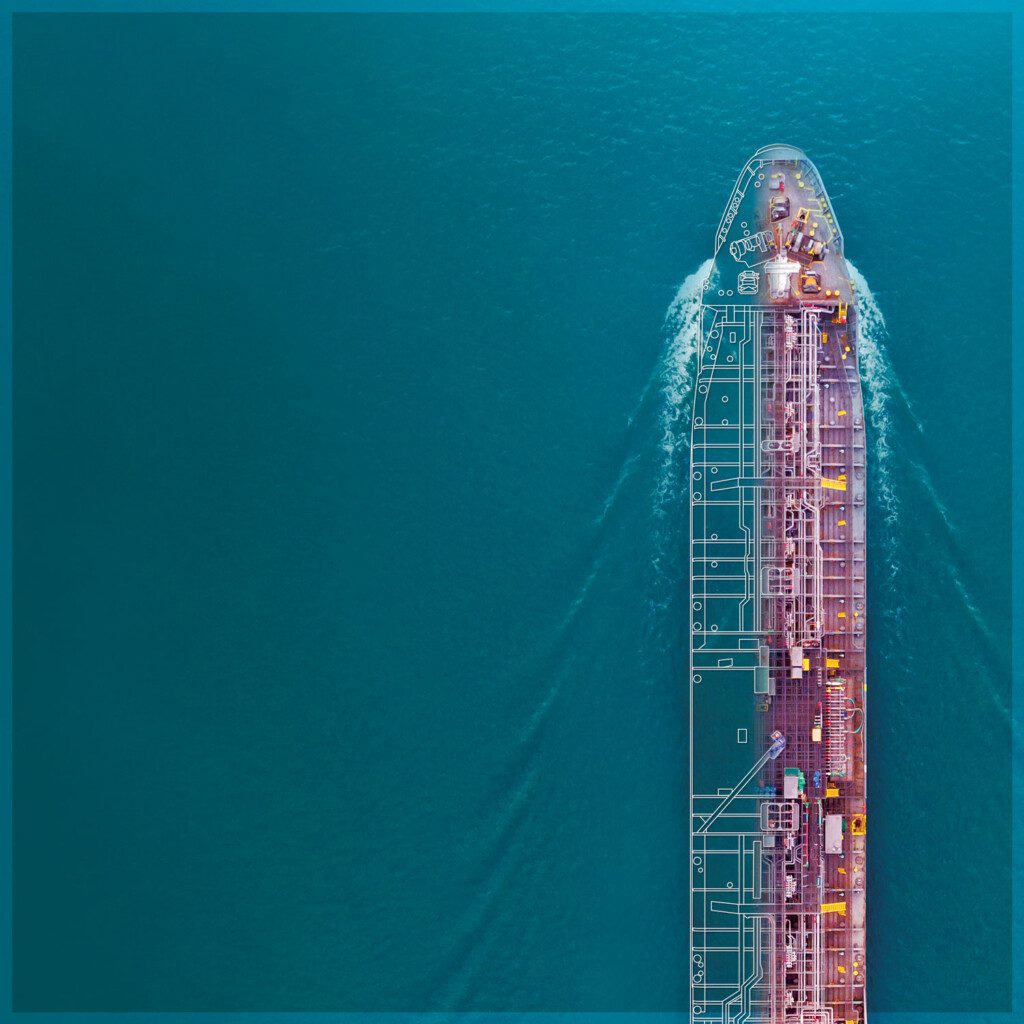

When your organization has the right tools and information throughout the design, build, and maintain processes, it is a massive advantage.

At each stage of your project, you should be able to take in the data from any other source, seamlessly work within industry specific standards and rules, and output documentation and information as needed. Doing so allows the best shipbuilders to see ROI on every project, or even on the current block about to be cut, no matter what.

What is ShipConstructor?

ShipConstructor is a suite of AutoCAD based software products designed for engineering and construction in the shipbuilding industry.

No matter what workflow you are used to, what platforms are used within your shipyard, or what types of projects you take on, the solutions you implement need to be shipbuilding specific and adapt to what works best for you.

ShipConstructor’s AutoCAD foundation provides a user environment that is a globally recognized standard. This results in an existing labor pool of expertise, a common DWG format for sharing information with other applications, and a portfolio of complementary Autodesk products.

Together, our suite of ShipConstructor Hull/Structure, Outfitting, and WorkShare products allows you to focus on what you do best – shipbuilding.

What can you do with ShipConstructor?

Hull / Structure Products

Hull / Structure Products

Outfitting Products

Outfitting Products

WorkShare Products

WorkShare Products

General Products

General Products

Who’s successful with ShipConstructor?

Huntington Ingalls Industries

Austal USA

Fincantieri – Marinette Marine

Royal Huisman

Robert Allan Ltd.

Seaspan ULC (Canada)

Drydocks World

Sumidagawa Shipyard

Miho Shipyard

ShipConstructor Hull / Structure Products

With a purpose built shipbuilding solution, the concepts, terminology, and functionality required for hull and structure modeling, basic and detailed design, and the engineering of blocks, parts, are included out of the box. That industry specific focus makes ShipConstructor a natural fit for your organization.

Hull

Hull combines purpose-built shipbuilding specific surfacing technology and the simplicity of working inside of AutoCAD.

This brings together the best of two worlds. It allows for easy and intuitive creation and manipulation of complex surface models while also allowing the freedom to use standard AutoCAD drafting techniques.

Structure

Structure offers rapid 3D production detailing of internal hull structure. It combines aspects of both associative and parametric 3D modeling but is tailored specifically to the design of ships and offshore structures.

Accurate and intelligent 3D project models can be created very quickly utilizing a cross section of shipbuilding specific capability and native AutoCAD tools.

WeldManagement

WeldManagement is a production and management system for structural welds in ShipConstructor.

This product provides the ability to fully customize weld symbols and standards. It also provides the ability to develop a weld schedule for each particular project. Once welds have been defined in the project (including automatic identification and weld path generation) configurable weld reports can be generated for any assembly, or for the entire project.

Nest

Nesting is tightly integrated into the central project database, providing features to nest by assembly, stock, material, surface treatment, port/starboard, like/mirror cut, and full remnant control.

Nest provides standard tools to align parts and insert bridges.

NC-Pyros

NC-Pyros reliably creates NC-Code for any type of NC-cutting machine: oxy-fuel, plasma, laser, water-jet, or router. The integration with the product model automatically feeds back important information such as estimated cutting time, processing date, and operator name. This completes report data and simplifies any recalls.

NC-Pyros-Bevel allows for adding variable angle cut and multi-torch weld preparation to NC-Pyros.

Outfitting Products

Your team needs to be able to complete accurate outfitting models in a way that works best with your existing workflows. Moving seamlessly to the outfitting stage, minimizes rework and can fundamentally impact how your design and engineering teams approach a project. ShipConstructor Outfitting offers a complete set of tools for piping, HVAC, electrical, equipment, penetrations, production detail reports, and build strategies.

Pipe

Pipe is a complete production design package for pipe systems. Its pipe modeling capability is spec-driven based on a user-defined parametric catalog of pipe stocks and standards with logical connections between parts in the model.

It features a powerful constraint-based modeling system which allows intuitive changes to existing piping systems. Pipe spools can be defined which are carried over into production for the creation of spool drawings and inclusion in the build strategy for pre-outfitting.

HVAC

HVAC (Heating Ventilation and Air Conditioning) integrates with all of the other ShipConstructor modules and encourages collaboration between departments.

HVAC can be based on a parametric catalog of stocks or can be driven by on-the-fly item creation depending on the client’s needs. The software employs the same constraint-based modeling engine used in Pipe.

Electrical

Electrical is a 3D modeling and production system for wireways, cable trays, supports, cables and transits. It features an associative 3D model connecting allocated space to individual wireways, cable trays, supports and subsequent cables. Associative production documentation can be generated from the model including cable pull schedules and reports. The cables within the model are automatically routed within the ShipConstructor environment according to EMC ratings, minimum bend radius and more.

Penetrations

Penetrations allow the creation of intelligent penetrations through structural members.

The parametric spec-based penetration standards support features such as multi-pipe (and HVAC) penetrations and penetration accessory items.

ShipConstructor WorkShare Products

Every modern shipbuilder has, to a certain degree, to work with professionals in different parts of the country, or the world. As a result, distributed teams are becoming increasingly common to see within shipbuilding organizations. Finding a way to ensure that teams in disparate locations, with different skills and abilities, can work on the same project and manage information regardless of format is key to making it possible to focus on shipbuilding.

Even when a project takes place in a single location, being able to share and reuse already completed blocks, assemblies, and other completed work with other ships in a series allows your organization to tackle one of the toughest challenges in shipbuilding. Transferring data across hulls and projects can fundamentally improve the traditional workflows in place.

A tool that effectively has those capabilities, and makes them easily accessible, allows an organization to:

- Work in sync on an entire project or model from multiple locations.

- Reuse entire blocks or systems along with the associated assembly information and production drawings.

- Control who can make changes to the model or production output.

Having granular control over how teams interact with each other and the rest of an organization, no matter where they are in the world, brings the benefits of shipbuilding’s global nature and mitigates the risks.

WorkShare Teams

WorkShare Teams is an additional solution to support distributed teams that share ShipConstructor work on a common project.

WorkShare Teams provides real-time access to a ShipConstructor project across multiple geo-locations.

WorkShare Transfer

One of the greatest challenges in shipbuilding today is managing changes across a series of hulls.

When collaboration across organizations is involved, the challenge of managing those changes is compounded, even when working on a single hull.

WorkShare Model

WorkShare Model allows you to transfer individual parts across different projects. This allows you to replicate elements of the 3D model at granular level of detail or share those elements to necessary stakeholders.

ShipConstructor General Products

Throughout the entire shipbuilding process, certain realities hold true. It is always critical to visually understand the model you are working with, work with drawings in a way that fits your workflows, manage equipment efficiently, report on progress, and understand your build strategy. These tools help you do what you do better, no matter what part of the lifecycle your project is in.

ShipExplorer

With hundreds of thousands of parts in a single CAD model, a way to quickly see what’s changed gives you the power to focus on the task at hand. ShipExplorer allows any stakeholder, CAD designer, or non-CAD/CAM user to quickly share design changes, inspect models, and communicate necessary revisions to whoever needs the information.

ShipExplorer makes it easy to:

- Use the switchback feature to open the related model drawing within ShipConstructor.

- Load and compare revisions between model drawings.

- Load the product hierarchies and create sets from the hierarchies for easy navigation.

- Use the embedded Search tool to find specific parts.

- Review drawings, compare design changes, and communicate complex data models across local and wide area networks.

- Quickly isolate selected objects and understand their orientation with the click of a button.

MarineDrafting

In a world of 3D design and manufacturing, many activities still need to be supported with 2D drawings during design and throughout the shipyard. Using shipyard standards, MarineDrafting allows the creation of 2D approval and workshop drawings directly from the 3D model.

These drawings are created in AutoCAD DWG format and remain associatively linked to the 3D model as changes happen.

Equipment

Equipment provides the ability to insert any type of equipment item into a ShipConstructor model. The equipment items can be modeled in almost any modeling software, including directly in AutoCAD, and then incorporated into the ShipConstructor database. At this point, HVAC and Pipe connections are added as well as production specific attribute information. Once standards have been defined, they are ready to be placed in the model.

Report

ShipConstructor provides a flexible, powerful tool for generating non-graphical production information. The Report module allows for the definition of complex production detail reports that can be generated from the central project database on demand. With advanced features such as grouping, sorting, summary fields and full control over the visual aspects of the report, this tool provides the means to extract the information required for the entire team. Any report can be exported to formats such as Microsoft Excel for further calculation and analysis.

ProductHierarchy

ProductHierarchy is the hub within a project for production preparation. The build strategy is the primary product hierarchy, which defines the assembly sequence for the project. Every part produced in each of the various modules has a place in the build strategy. Planning and scheduling departments define the build strategy to optimize the logical sequence of assembly based on production capabilities together with need-by and procurement dates. All ShipConstructor production output functions are driven by the build strategy, allowing for near-automatic generation of production drawings.